With 24/7 monitoring and algorithms tailored to your building’s equipment and control sequences, we confirm proper HVAC operation and identify hardware and controls issues.

Automated Commissioning

-

Identify and prioritize HVAC issues

-

Track building performance

-

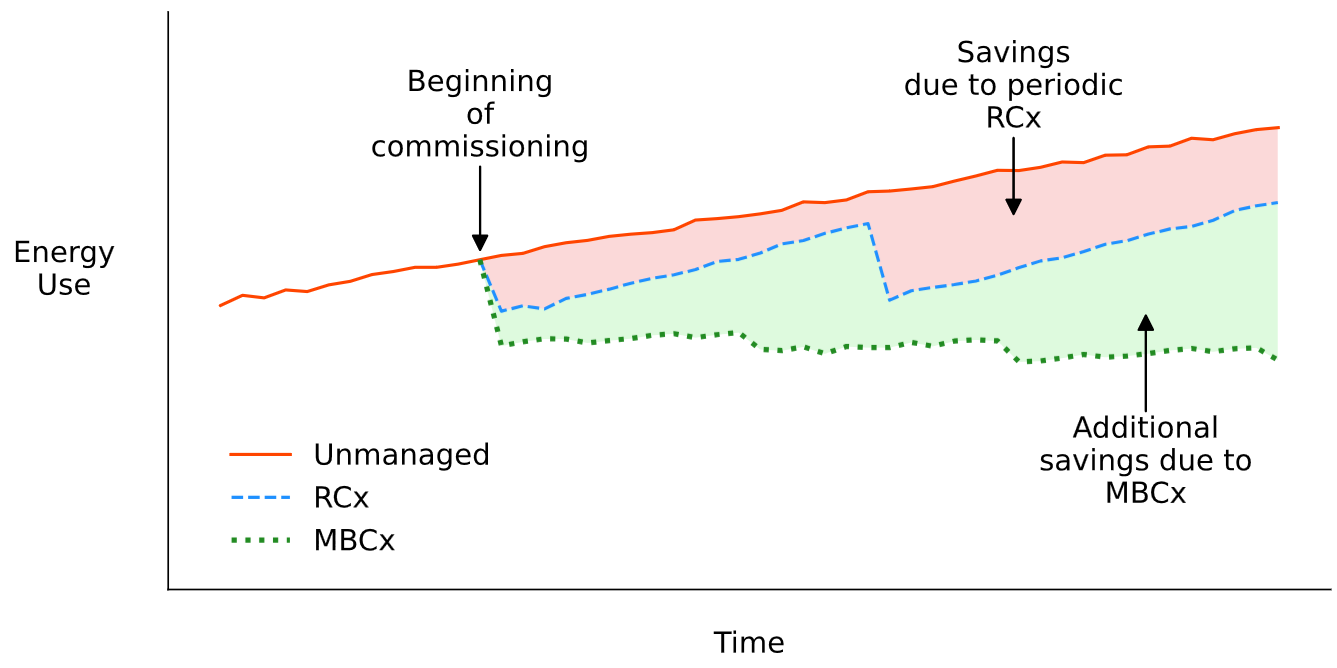

Save time, energy, and money

Use Cases

Existing buildings

New construction first-year tuning

Fault Type Examples

Valve leakage / failure

Damper leakage / failure

Sensor and AFMS drift / failure

Reset controls not working as expected

Component status/command disagree

Linked component commands disagree—e.g., RAF/EAF/BEF not on with SAF

Schedule and control on/off disagree

Zone override and SAF command disagree

Safety control and alarms improperly triggered or not triggered

Control point outside acceptable variation of setpoint and operating at min or max capacity

Economizer not providing free cooling when capable or providing excessive outside air and increasing heating and cooling loads

Excessive cycling of analog component—e.g., fan, pump, or non-hydronic coil

Components returned to undesired position or setting when disabled

Components improperly staged or positioned

Root Cause Analysis

Identify which component has failed, and how it has failed, in a multi-component system

Asset Monitoring (In development)

Know the optimal time to “rod out” a shell-and-tube heat exchanger

Know the optimal time to clean coils and filters

Meter Analytics (In development)

Detect undesired cycling and unintended off-hours operation of large equipment

Compare performance of facilities at the portfolio level